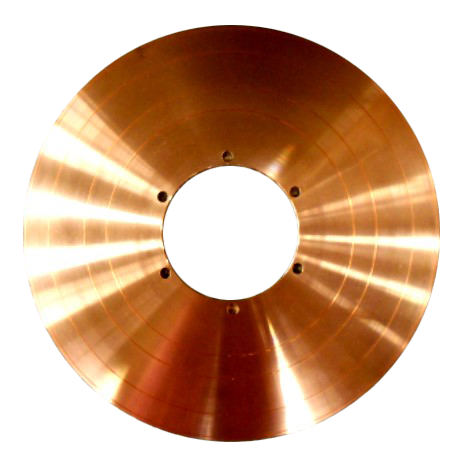

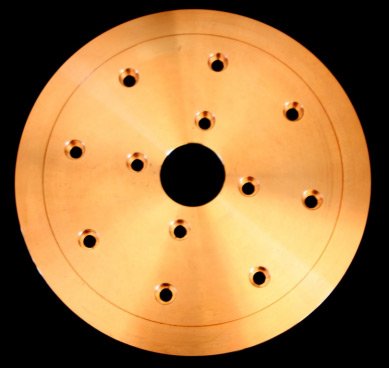

SEAM WELD WHEELS & BLANKS

Cadi Company is an ISO certified manufacturer and distributor of seam weld wheel blanks and finished wheels using RWMA Copper Alloys.

Cadi Company has:

- A tailored process for individually hot forging blanks consistent with best metallurgical processes.

- A proprietary process that yields maximum hardness while maintaining necessary ductility.

- A metallurgically engineered process that yields optimum grain structure.

Cadi weld wheels are made from RWMA Class 2 (C18150 and C18200) and RWMA Class 3 (C18000 and C17510) copper alloys. Cadi Class 2 wheels are specially forged to increase hardness to 75Rb minimum. Wheel blanks are in stock to 30” in diameter.

Cadi understands the metallurgical issues of seam welding wheel manufacturing. We have applied this knowledge to develop a proprietary process that consistently delivers quality seam welding wheels for demanding applications.

| RWMA CLASS | UNS | Hardness RB |

Electrical Conductivity %IACS |

Applications |

| Class 2 | C18200 CuCr |

65 min | 75 min. | Hot-rolled steel |

| Class 2 Premium | C18150 CuCrZr |

75 min | 75 min. | Coated Materials Galvanized Steel |

| C18200 CuCr |

Premium grade for hot-rolled steel used with higher pressures | |||

| Class 3 | C18000 CuNiSiCr (Beryllium free) |

90 min | 45 min. | Stainless Steel High temperature Steels |

| C17510 CuNiBe |

|